Why You Should Always Choose Carbide Tools Over Steel

Steel Versus Carbide Cutting Tools

The use of the right professional trade tools to cut, shape, and grind your products will help you maximize your potential. Cutting tool users cannot afford to ignore the advancements made in the materials used for tool technology. Anytime there is a change in ingredients, and performance comparison is necessary before the user can select a specific tool for his job. Carbide cutting tools have an extra component of either tungsten or titanium that makes them have an advantage over steel-made models. Carbide tools are more reliable and stronger in terms of performance and resist abrasion so well, but more expensive than steel. Tools containing carbide can withstand high temperatures than steel, allowing faster machining. Carbide bits and cutters maintain a sharp edge, and produce an excellent finish, giving a clean and smooth cut after cutting. The bits, blades, and knives also do not allow chattering, thus reducing the chances of failure. There are several popular carbide tools for your work. For instance, you can buy router bits, masonry bits, planer knives, shaper cutters, and many more from home improvement stores. Use of carbide cutting tools has several advantages over steel:

- Cost-Effectiveness

When purchasing these tools, the cost might seem expensive. However, with time, you will end up saving a lot of money when it comes to wear and tear. Carbide tools withstand a lot of heat, and you will not be required to stop and wait for the machinery to cool off. Dissipation helps tools to maintain their structure and stay for long, thus increasing their mileage and production cycle times. Besides, high tolerance to extreme heat allows for a high revolution per minute cutting speeds.

- Easy Replacement of Tips and Cutters

Carbide tips and blades are much easier to replace than having to replace the whole set of tools. When having a tipped model, in case of a fracture, you need to grind off the old carbide and replace it with a new layer, keeping the rest of the tool intact. Carbide tipped models have fewer maintenance issues, and they maintain hardness even when subjected to compression, so in the long run, they become effective and very efficient.

- Clean Cuts and Finishes

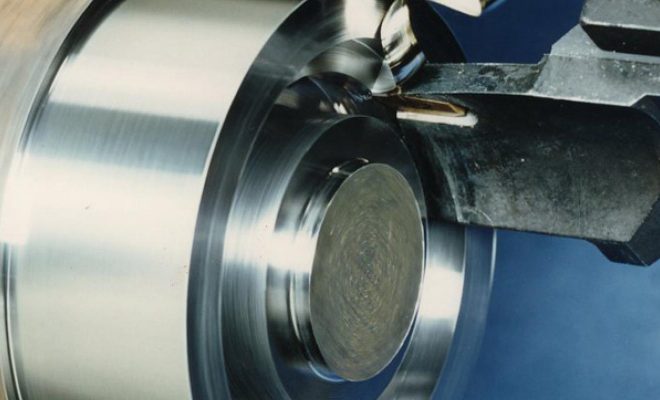

Carbide cutting edges stay sharper for longer, unlike steel that wears down often. Carbide stays for a reasonable duration before it starts to appear dull. Because of the sharp edge, they produce a clean and neat finish than steel. Whether in woodworking, routing tools, or power tools, a clean finish saves the user both their time and money. Polishing imperfections means damage on devices and wastage of productive time that could otherwise be used for other income-generating works. Woodwork does not damage the grains used to make carbide tools. As compared to steel, carbide gives better results.

- Long-Lasting

Carbide tipped models outlasts the working life of steel models due to their higher wear resistance. Also, the ability to replace carbide makes the tool last long. Replacing tips and cutters without swapping a new tool gives them more value making these tools the best choice. A combination of steel and the finishing power of carbide gives surety of a device that is built to last longer. The pricing may seem expensive at first, but there is value in the end. Carbide models are the superior option when working with polymers, cast iron, and glass-filled plastics because of their abrasive nature. In general, carbide tools have a longer working life than steel.

Cutting Tool Applications

When manufacturers are making tools, they assign different names and identification numbers to their products. In some instances, these names and numbers may appear to be similar. The tool user should first understand the components used to make these tools before making a purchase. For instance, the material used to make router bits may affect the usage of the tool in different wood and metal type of industry. So, tool users need to understand the benefits of using carbide cutting tools over steel thoroughly.