Anti Corrosion Coating Techniques for Metal Equipment

Equipment manufacturers continuously seek ways to improve the durability and longevity of their products, with a focus on reducing corrosion and wear in metal components. electroless plating in Texas, along with other metal coaters in the region, offers a variety of solutions to achieve these goals. This article will explore electroless nickel plating and industrial hard chrome plating as two key methods, including electroless nickel coating, for enhancing the performance and life expectancy of metal equipment, targeting men working in equipment manufacturing companies.

Electroless Nickel Plating: A Solution for Corrosion Resistance, Uniform Coverage, and Electroless Nickel Coating

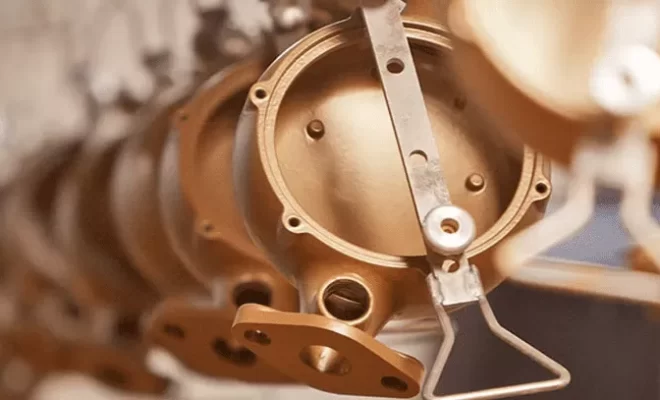

One of the primary methods employed by metal coaters in Texas is electroless nickel plating. This technique provides a consistent, uniform layer of nickel-phosphorus alloy over the surface of a metal component. Unlike electroplating, which relies on electric currents to deposit metal ions, electroless plating uses a chemical process to achieve the desired coating thickness.

Electroless nickel plating offers several advantages for equipment manufacturers:

1. Corrosion Resistance: The nickel-phosphorus alloy creates a barrier that shields the underlying metal from environmental factors, such as moisture, chemicals, and temperature fluctuations, which can lead to corrosion.

2. Uniform Coverage: The chemical process used in electroless plating ensures even coverage across the entire surface of the component, including complex geometries and internal features that are challenging to reach using other coating methods.

3. Electroless Nickel Coating: This coating not only offers corrosion and wear resistance but also provides a consistent layer that enhances the performance of the metal components, ensuring a longer service life.

4. Improved Solderability: Electroless nickel coatings enhance the solderability of metal parts, simplifying the assembly process for electronic components.

Industrial Hard Chrome Plating: A Solution for Wear Resistance and Extended Lifespan

Industrial hard chrome plating is another technique employed by metal coaters in Texas to enhance the durability and performance of equipment. This process involves the deposition of a thin layer of chromium onto a metal surface, typically using an electroplating method. Industrial hard chrome plating offers numerous benefits for equipment manufacturers:

1. Wear Resistance: The hard chrome layer provides exceptional wear resistance, prolonging the service life of components subjected to friction, abrasion, or erosion.

2. Corrosion Resistance: Hard chrome plating adds a protective barrier against corrosion, making it suitable for use in harsh environments or applications exposed to chemicals.

3. Low Coefficient of Friction: The smooth surface created by hard chrome plating reduces friction between moving parts, minimizing wear and enhancing overall performance.

4. Restorative Properties: Hard chrome plating can be used to restore worn or damaged components to their original dimensions, saving manufacturers time and resources on replacement parts.

Publication: Industrial Maintenance & Plant Operation (IMPO) Magazine

For industry professionals interested in the latest advancements and best practices in equipment manufacturing and maintenance, Industrial Maintenance & Plant Operation (IMPO) Magazine is a valuable resource. The publication covers topics such as coatings, lubrication, and corrosion prevention, making it an ideal platform for sharing information on electroless plating in Texas and the benefits of metal coaters in the region.

Conclusion

In the equipment manufacturing industry, durability and performance are critical factors in determining the success and reputation of a company’s products. By utilizing electroless nickel plating, including electroless nickel coating, and industrial hard chrome plating, metal coaters in Texas can provide manufacturers with solutions that enhance corrosion resistance, wear resistance, and overall component lifespan. By incorporating these techniques into their production processes, equipment manufacturers can ensure that their products offer superior performance and reliability in even the most demanding applications.