Why Industrial Belts Are Key to Power Transmission and Performance

What keeps heavy-duty machines moving with strength and precision? It often comes down to the efficiency of the parts behind the scenes. Industrial belts are one of those silent workhorses doing critical jobs. Let’s explore why these components are so vital for smooth and reliable performance.

The Power Behind Performance

Industrial belts play a central role in transferring energy from one component to another. Many industries rely on quality brands like Jason Industrial Belts, which are engineered to provide consistent, dependable power transmission. They help drive machinery in manufacturing, agriculture, HVAC systems, and more. Without strong belts in place, operations can face downtime, wear, and performance loss.

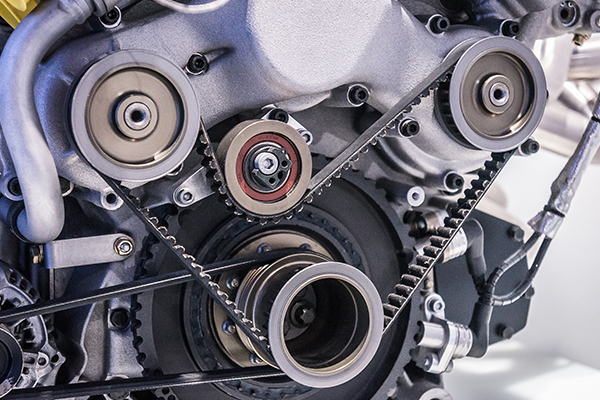

A belt must withstand force, speed, tension, and temperature—maintaining flexibility while staying strong under pressure. This precise balance of durability and adaptability makes it ideal for high-performance systems operating under demanding conditions. From conveyors to V-belts and timing belts, each type plays a unique role. When they perform well, machines operate smoothly. When they fail, everything comes to a stop.

Types That Fit the Job

Industrial belts aren’t one-size-fits-all. Each type is built for a specific role in power transmission and performance.

- V-belts are ideal for machines that require high torque.

- Flat belts deliver smooth, consistent motion in light-duty or precision-based applications.

- Timing belts ensure that parts move in perfect sync, which is essential in systems needing exact control.

- Specialty belts offer added grip or resistance to heat, making them suitable for tough environments.

Belt selection must align with pulley size, tension demands, and equipment layout. Selecting the wrong type can lead to wear, inefficiency, or system failure. That’s why proper matching from the start is so important.

What to Expect from a Premium Supplier

Working with a trusted source makes all the difference. A premium supplier doesn’t just ship parts—they understand what performance looks like. They help match belt types with equipment demands and can suggest better alternatives when needed. Materials, construction methods, and specifications are all considered. This kind of guidance saves time and prevents costly trial and error.

Many rely on premium suppliers because they offer a full range of belt types suited for different applications. They provide reliable performance data and product specifications that help guide informed decisions. Fast shipping and consistent inventory levels make it easier to avoid downtime. Expert product recommendations ensure the right fit from the start. Dedicated support is available both before and after a purchase.

Why Maintenance Matters So Much

No matter how well-built, a band needs regular checks. Wear and tear over time can lead to cracks, stretching, or slipping. Even a small misalignment can cause serious performance issues. That’s why scheduled maintenance is critical in high-use environments. Technicians look for signs of damage and measure belt tension as part of routine inspections. These simple steps help prevent bigger issues down the line.

Proper installation is also key. If a belt is too tight, it can wear out faster. If it is too loose, it may slip or fail under load. Cleaning debris, checking pulleys, and replacing belts before failure are all smart practices. A well-maintained band system keeps energy loss low and efficiency high.

When Efficiency Matters Most

In industries where every minute counts, even small improvements can make a big impact. High-quality products reduce energy waste, extend machine life, and cut down on unexpected stoppages. They help equipment perform at its best while reducing the need for constant repair. This efficiency supports both productivity and cost savings over time. Companies that rely on machinery often find that belt quality directly impacts their bottom line.

In high-performance environments, reliability isn’t optional—it’s essential. That’s where trusted brands make all the difference. Jason Industrial Belts are a prime example—renowned for their durability and consistent performance across a wide range of industries. While they operate behind the scenes, their impact is anything but hidden: machines run more efficiently, safely, and for longer periods. This reliability allows businesses to focus on progress, not problems. A supplier that understands both product and purpose becomes a true partner in achieving long-term efficiency.